Procedure for Preparation And Standardization of 1N NaOH:

Reagents used for 1N Sodium Hydroxide:

- 95% Alcohol

- Phenolphthalein Indicator

- Carbon Dioxide Free water

Preparation of Reagent:

95% Alcohol: Mix 95% of absolute alcohol with 5ml of water.

Phenolphthalein Indicator: Dissolve 1 g of Phenolphthalein in 100ml of 95% alcohol.

Carbon Dioxide free water: The water which has been boiled vigorously for a 5 min or more and allow to cool protected from the adsorption of carbon dioxide from the atmosphere or purified water that has a resistivity of NLT 18 Mohm-cm.

Preparation of 1N Sodium Hydroxide (1N NaOH):

- Take 200ml dried beaker.

- Add about 162g of sodium hydroxide in 150 ml of carbon-dioxide free water.

- Dissolve it and cool the solution to room temperature.

- Fiilter the soolution through hardened filter paper.

- Transfer 54.5 ml of filtrate to a tight, polyolefin container.

- Dilute the solution with water to 1000 ml.

Standardization of 1N Sodium Hydroxide (1N NaOH):

- Weight accurately 5g of potassium bi-phthalate (potassium hydrogen phthalate), previously crushed and dried at 120°C.

- Dissolve it in 75ml of carbon di-oxide free water.

- Add 2 drops of phenolphthalein indicator solution.

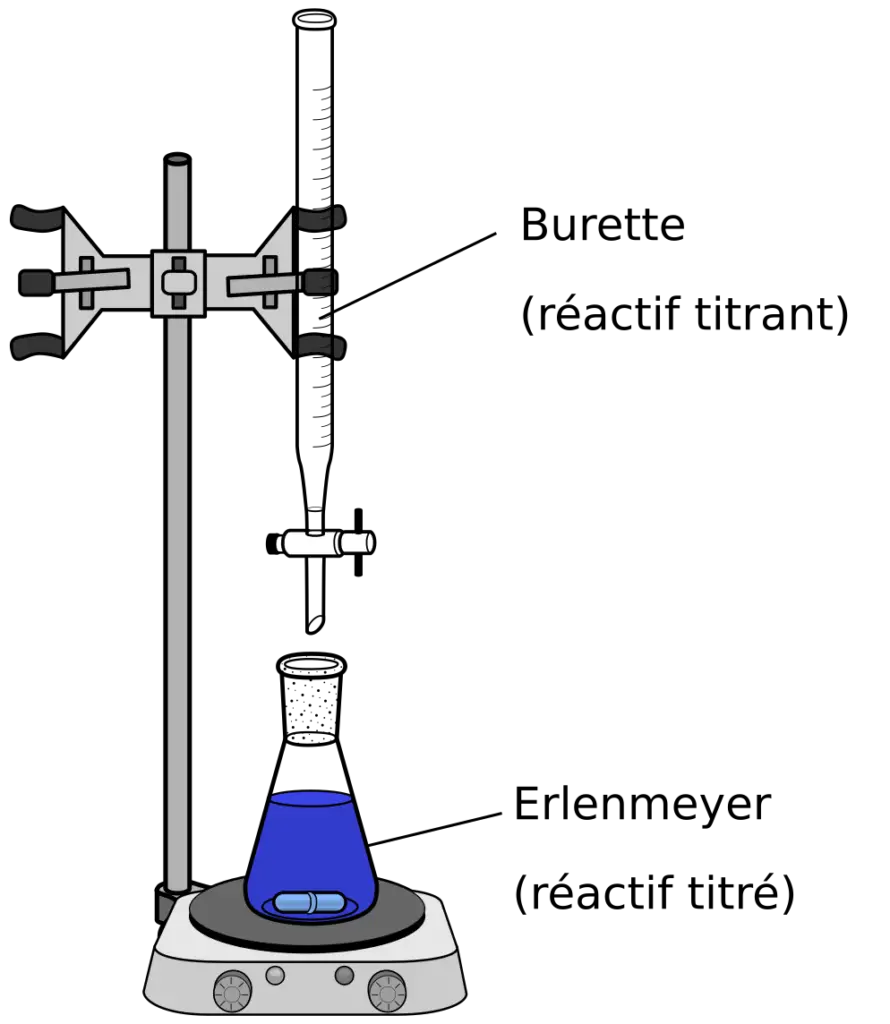

- Titrate the solution with 1N sodium hydroxide to the production of permanent pink color.

Calculation of Normality of Sodium Hydroxide:

Normality of Sodium Hydroxide = W/0.20422 x V

Where,

W= Weight of potassium hydrogen phthalate in g,

V= Volume of Sodium Hydroxide consumed in ml.

This is the procedure for Preparation And Standardization of 1N NaOH in pharmaceuticals.

Also Read:

- How to prepare 0.1M HCl Solution

- Laboratory Investigation of aberrant results part-3

- Mechanical Calibration of Dissolution

- Difference Between Alcoa and Alcoa Plus

- Practices to avoid data integrity issues and alcoa plus

- Interview Questions and answers for QC

For interview preparation refer

YT channel: Pharmabeej